Sink selection and installation are crucial aspects of modern kitchen design. With the diversification of kitchen functions and innovative design styles, sink installation options are becoming increasingly diverse. Flush-mount sinks, a common and fashionable option, are gaining popularity among more and more families and designers.

A flush-mount kitchen sink features a sink rim recessed into the countertop, lower than the surface, creating a smooth transition between the countertop and sink, both aesthetically pleasing and easy to clean. With sinks of various materials entering the market, many consumers wonder whether all sinks can be flush-mounted.

This article will explore this question in detail, analyzing the compatibility of flush-mount sinks with different materials to provide a deeper understanding of this design option.

What is a flush-mount kitchen sink?

The installation method of a flush-mount kitchen sink differs from that of a traditional above-counter sink. While above-counter sinks typically have a rim that protrudes from the countertop, a flush-mount sink's rim is recessed into the countertop. This method eliminates protrusions at the seam between the sink and the countertop, creating a smooth surface. This not only enhances the overall aesthetic but also makes cleaning easier. Common materials for flush-mount sinks include stainless steel, ceramic, and composite materials, suiting a variety of kitchen styles and functional requirements.

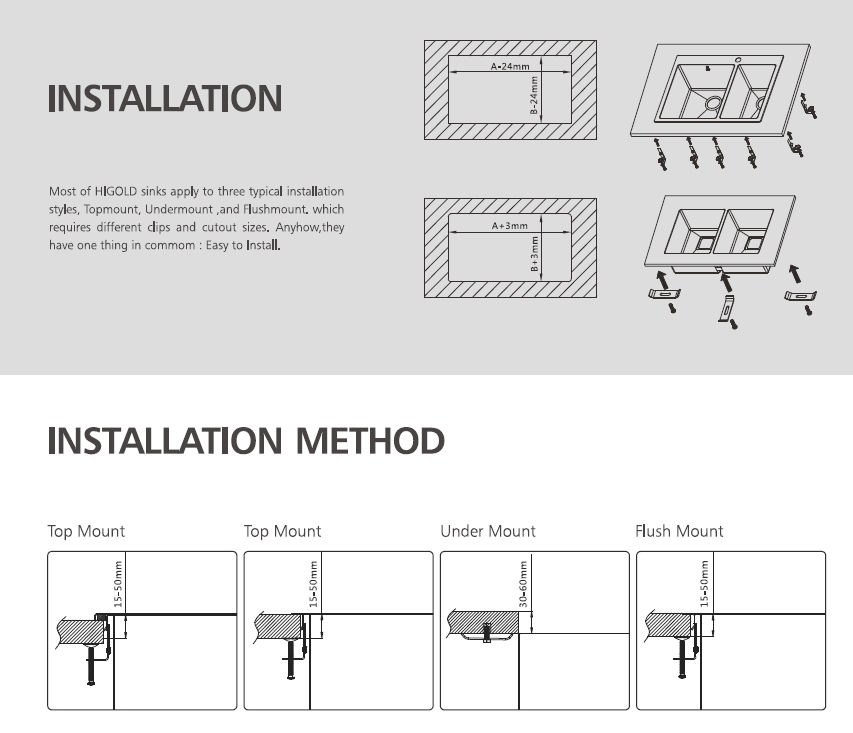

How does a flush-mount sink install?

A flush-mount installation involves recessing the sink rim into the countertop. The connection between the sink and the countertop is secured with adhesive and support brackets. Typically, a notch of appropriate size is cut into the countertop during installation, into which the sink is inserted, ensuring a secure and smooth integration with the countertop.

This installation method not only ensures a clean and aesthetically pleasing appearance, but also eliminates protrusions or gaps at the seam between the sink rim and the countertop during cleaning, minimizing the accumulation of water stains, grease, and other contaminants.

Can any sink be flush-mounted?

When choosing a sink material, consumers often face a variety of options, including stainless steel, ceramic, quartz, and composite. Each material has different properties, so when considering whether it's suitable for flush-mount installation, a detailed analysis of the material's characteristics is necessary.

1. Stainless Steel Sinks

Stainless steel sinks are currently the most common sink material, popular among consumers for their durability, corrosion resistance, and ease of cleaning. Recessed installation is particularly common because stainless steel offers excellent toughness and strength, making it less susceptible to breakage or damage during processing and cutting.

• Suitability: Stainless steel sinks are perfectly suited for flush-mount installation due to their excellent plasticity and durability. Their smooth and durable surface finish prevents cracking or deformation caused by the pressure of installation.

• Installation Tips: During installation, stainless steel sinks require precise cutting of the edges, as they may have sharp edges during installation. Sanding or edge sealing is necessary to prevent scratches on countertops or other surfaces.

2. Ceramic Sinks

Ceramic sinks are favored by some families for their high-end, elegant appearance and excellent stain resistance. Ceramic sinks are typically made of high-temperature fired porcelain, offering excellent hardness and corrosion resistance, but they can also be somewhat brittle.

• Compatibility: Ceramic sinks require special care during installation due to their fragile nature. While recessed installation is possible, ceramic sinks are particularly brittle, especially around the edges, which can be easily cracked by impact. Therefore, it's important to consider the sturdiness of the countertop support structure.

• Installation Tips: Ceramic sinks should be installed with care to avoid strong impacts or excessive pressure. Before installation, ensure the proper fit of the sink to the countertop and use a dedicated support bracket to secure the sink in place for stability.

3. Quartz Sinks

Quartz sinks are made from a composite of quartz and resin, offering excellent stain and scratch resistance. Their texture and appearance resemble natural stone, making them suitable for high-end modern kitchens.

• Compatibility: Quartz sinks are generally well-suited for recessed installation due to their hardness and excellent pressure resistance. Compared to stainless steel sinks, quartz sinks are more scratch-resistant and offer a more refined appearance, often becoming a focal point in kitchen designs.

• Installation Tips: Quartz sinks require specialized tools for cutting and installation, ensuring smooth, even edges. Due to their weight, special attention should be paid to the countertop's load-bearing capacity during installation to avoid displacement or damage due to insufficient support.

4. Composite Sinks

Composite sinks are typically made from a blend of various materials, such as composite resin and natural stone chips. Commonly found in modern kitchens, they offer heat and corrosion resistance and are often available in a variety of colors, making them suitable for a variety of styles.

• Adaptability: Composite sinks are durable, stain-resistant, and scratch-resistant, making them ideal for flush-mount installation. Composite materials are also highly machinable and can be cut and carved to fit various sizes.

• Installation Tips: Composite sinks are relatively lightweight, but their fit with the countertop should still be considered during installation. Ensure the edges are completely flat and use appropriate fixings to prevent loosening during use.

5. Copper Sinks

Copper sinks are popular with some consumers for their unique appearance and natural antibacterial properties. While copper is corrosion-resistant, it is less hard than other materials and is susceptible to damage from physical impact.

• Compatibility: Copper sinks can be flush-mounted, but because copper is relatively soft, it can easily deform under external forces. Therefore, special care must be taken during installation to ensure the sink is not subjected to excessive impact.

• Installation Tips: Copper sinks require soft tools for fixing to avoid damage. During installation, the countertop support structure must be sufficiently stable, and the edges of the sink must be smooth and free of sharp edges.

As can be seen from the above analysis, not all sink materials are suitable for flush-mount installation. While sink materials like stainless steel, quartz, and composite materials generally meet flush-mount installation requirements, more fragile materials like ceramic and copper sinks require extra care during installation to ensure they are not damaged by external forces.

When choosing a flush-mount sink, consumers should consider the sink material, the countertop's load-bearing capacity, the installation difficulty, and their own needs. When selecting a material, consider both aesthetics and functionality, as well as durability and compatibility.

When selecting and installing a sink, it's best to consult with a professional kitchen designer or installer to ensure the perfect fit between the sink and the countertop, ensuring a superior user experience after installation.

Why is Higold considered a leading manufacturer in China?

Since 2004, Higold has developed into a global kitchen hardware company with advanced production technology, 500+ patents, and strong sales performance. With annual sales exceeding USD 50 million, Higold consistently supplies international buyers with high quality, low price stainless steel sinks. We are a trusted factory in China for customized ODM manufacturing, wholesale supply, and reliable global sales channels.