In modern home decoration, handmade stainless steel kitchen sinks have gradually become a standard feature of high-end kitchens. They are popular for their clean lines, spaciousness, and premium feel. However, when purchasing these sinks, people are often troubled by one question:

"Is a thicker steel plate for a handmade stainless steel kitchen sink always better?"

This article will analyze the relationship between stainless steel thickness and the quality of handmade sinks from a professional perspective, helping you scientifically determine the most suitable thickness.

What is a "Handmade Stainless Steel Kitchen Sink"?

1. The Difference Between Handmade Sinks and Pressed Sinks

Before discussing thickness in depth, it is essential to understand the concept of a "handmade stainless steel kitchen sink."

Stainless steel sinks on the market are mainly divided into two categories:

• Pressed Sinks: These are formed by pressing thin stainless steel sheets into shape in one go using high-tonnage molds. They have a smooth structure and low cost, but the sheet material is relatively thin (generally 0.6mm to 0.8mm).

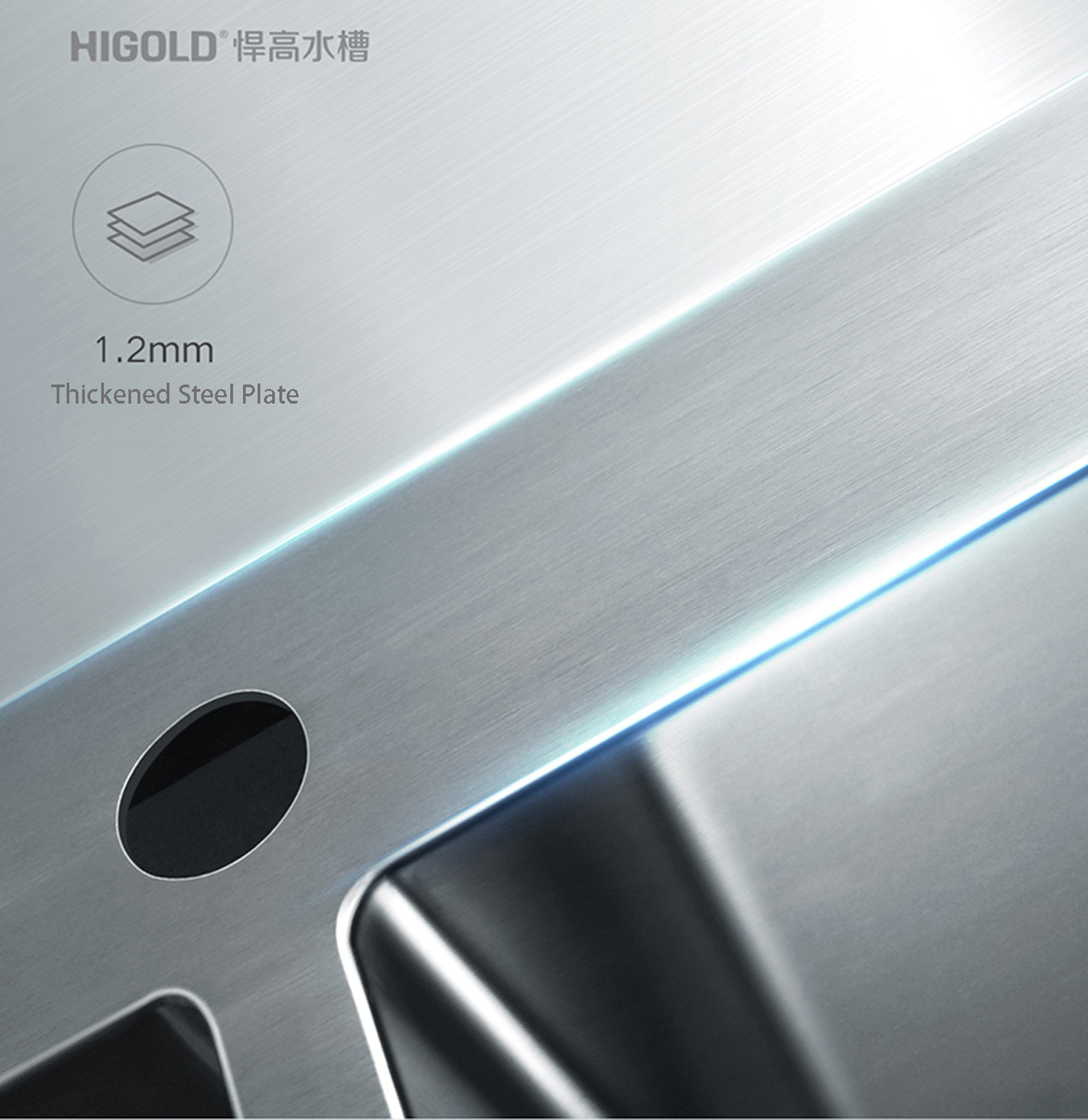

• Handmade Sinks: These are made by hand from thicker stainless steel sheets through bending, welding, and polishing. They have sharp edges, a deeper body, and a more upscale feel. The thickness is generally 1.0mm to 1.5mm.

2. Manufacturing Characteristics of Handmade Stainless Steel Kitchen Sinks

The handmade sink manufacturing process demands extremely high standards in welding and polishing. Its edges are usually straight or at 90° angles, resulting in more internal space and higher utilization. Furthermore, the surface is typically brushed or matte, giving it a clean, scratch-resistant, and easy-to-clean appearance.

Therefore, thickness plays a more critical structural role in handmade sinks, affecting not only stability but also aesthetics, noise control, and lifespan.

Why is thickness an important factor when choosing a handmade stainless steel kitchen sink?

Thickness is a crucial physical parameter for measuring the quality of a handmade stainless steel kitchen sink. It directly determines the sink's resistance to deformation, impact resistance, and lifespan.

1. Thickness Affects Structural Strength

The greater the thickness, the stronger the steel plate, and the less prone it is to deformation due to external forces or installation pressure. For hand-welded sinks, the strength of the weld joint is closely related to the thickness of the sheet material; a thicker plate can better withstand the heat deformation during welding.

2. Thickness Affects Noise and Vibration

Thin-walled sinks are prone to resonance during washing dishes or water dispensing, producing a "metallic echo" or "thumping" sound. Thick-walled sinks are quieter under the same conditions, especially when combined with bottom anti-vibration pads, resulting in superior sound insulation.

3. Thickness Affects Appearance Smoothness

Thicker sheet material is less likely to spring back after bending and forming, resulting in sharper and smoother edges and lines. Therefore, high-end handcrafted stainless steel kitchen sinks often use a thickness of 1.2mm or more to ensure a three-dimensional appearance and shape stability.

4. Thickness Affects Installation Method

Sinks that are too thin are prone to deformation when embedded in the countertop and are difficult to secure; while sinks that are too thick may increase the overall weight and make installation more difficult. Therefore, a thickness between 1.0mm and 1.2mm is often considered the "balance point between engineering and aesthetics."

What is the common thickness for handcrafted stainless steel kitchen sinks?

Different brands, intended uses, and installation requirements will result in slight variations in thickness. The following are common thickness ranges and characteristics:

Thickness (mm) | Features | Applicable Situations |

| 0.8mm | Thinner, low price, easily deformed | Economy products, lightly used kitchens |

| 1.0mm | Standard thickness, high cost-performance ratio | Most family kitchens |

| 1.2mm | High-end thickness, structurally stable | Mainstream thickness for hand-welded sinks |

| 1.5mm | Extra-thick type, strong impact resistance | Commercial kitchens, large sink designs |

As can be seen, 1.0-1.2mm is the optimal thickness range for household use. While sheets thicker than 1.5mm are sturdier, they are more expensive, more difficult to process, and have limited practical value.

Is thicker always better for handcrafted stainless steel kitchen sinks?

1. From a structural perspective: There is an upper limit to thickness increases

Moderately increasing the thickness can indeed enhance the stability and lifespan of the sink. However, beyond a certain range (such as exceeding 1.5mm), the benefits diminish significantly. For example:

• Limited increase in strength from thicker sinks;

• Significantly increased weight, making installation more difficult;

• Increased cost, but little improvement in daily user experience.

Therefore, "thicker is always better" is not scientifically sound; rather, the intended use, installation method, and overall balance must be considered.

2. From a sound control perspective: Thickness isn't the only factor

While thickness can improve noise levels, the addition of shock-absorbing and sound-dampening pads is more crucial. Many high-end handcrafted stainless steel kitchen sinks with a thickness of 1.0mm still achieve good noise reduction through the combination of bottom shock-absorbing pads and anti-condensation coatings.

3. From a user experience perspective: Excessive thickness reduces elasticity

An excessively thick stainless steel surface lacks resilience when impacted with objects, making it feel stiffer when washing dishes and more prone to cracking ceramic tableware. This is a "hidden side effect" of excessive thickness.

The impact of Thickness on Stainless Steel Material Performance

1. The thickness difference between 304 and 316 stainless steel

Handcrafted stainless steel kitchen sinks commonly use 304 stainless steel (containing 8% nickel and 18% chromium), which has good rust and corrosion resistance. Some high-end sinks use 316 stainless steel, which has stronger resistance to acids and alkalis.

Because 316 has slightly higher strength, under the same structural conditions, 316 material can be used at a slightly thinner thickness (e.g., 1.0mm) while still maintaining sufficient rigidity.

2. Relationship between Thickness and Surface Finish

Thicker stainless steel is better suited for high-end surface finishes such as brushing and sandblasting, maintaining a smooth surface and resisting deformation. Conversely, thinner sheets are prone to ripples or uneven reflections during surface processing, affecting aesthetics.

3. Thickness Has No Direct Relationship with Corrosion Resistance

Thickness does not determine rust resistance. Corrosion resistance mainly relies on the formation of a passivation film (chromium oxide layer) on the stainless steel surface. As long as the material is qualified, the rust resistance of 0.8mm and 1.2mm is essentially the same.

What are the Pros and Cons of different thicknesses of handmade stainless steel kitchen sinks?

Thickness range | Advantages | Disadvantages |

| Below 0.8mm | Affordable price, lightweight | Prone to deformation, high noise, low weld strength |

| Around 1.0mm | High cost-performance ratio, sturdy and durable | Requires high welding skills |

| 1.2mm | Excellent stability, high-end appearance | Slightly higher cost, increased weight |

| Above 1.5mm | Extremely strong structure, virtually vibration-free | High cost, inconvenient installation, exceeds household needs |

For most families, a thickness of 1.0–1.2mm is ideal for handmade stainless steel kitchen sinks, ensuring structural strength while also considering comfort and ease of installation.

How well does the thickness of handmade stainless steel kitchen sinks match the manufacturing process?

1. Relationship between Welding Quality and Thickness

The thicker the sheet, the deeper the weld, and the higher the requirements for welding heat control. High-quality handmade stainless steel kitchen sinks typically employ TIG welding to ensure smooth, crack-free welds. Welding becomes significantly more difficult and costly when the thickness exceeds 1.5mm.

2. Difficulty in Bending and Forming

Stainless steel thicker than 1.2mm requires greater pressure and more precise molds during bending. Therefore, excessive thickness increases manufacturing difficulty and makes it harder to maintain precise edge lines.

3. Surface Grinding and Polishing

Thicker plates exhibit stronger wear resistance during grinding, are less prone to "blueing" or uneven brushing, and have a finer visual texture. However, excessive thickness increases grinding time and cost.

How to Correctly Determine the Thickness When Purchasing a Handmade Stainless Steel Kitchen Sink?

1. Check the Manufacturer's Specifications

Reputable brands will clearly indicate the material (e.g., SUS304) and thickness (e.g., 1.2mm). Be wary of sinks that only state "thickened" without specifying a value.

2. Measurement Method

You can measure the edge thickness using calipers (note that welded areas may be slightly thicker) to avoid being misled by false labeling. For example, some products are actually only 0.8mm thick but are advertised as "1.2mm sheet."

3. Choosing Thickness Based on Application

• Single-bowl sink: 1.2mm is recommended for strong impact resistance.

• Double-bowl sink: 1.0mm is recommended for a balance between weight and stability.

• Commercial or large-capacity sinks: Consider 1.5mm or thicker.

Besides thickness, what else should you consider when buying a handcrafted stainless steel kitchen sink?

Thickness is important, but it's not the only standard for evaluating sink quality. The following factors also affect the user experience:

• Material purity: Must be genuine 304 or 316 stainless steel;

• Surface finish: Brushed, matte, and fingerprint-resistant treatments determine the aesthetic appeal;

• Bottom design: Does it include shock-absorbing pads and an anti-condensation coating?

• Drainage structure: Is the drain outlet thickened, and are the accessories clog-proof?

• Welding process: Are the corner welds smooth and free of black spots?

• Brand reputation and warranty: Reputable manufacturers provide more stable quality assurance.

In other words, thickness is only one of the "hard indicators"; what truly determines the user experience is the comprehensive design and manufacturing details.

Does Higold provide product guarantees?

Yes, all Higold sinks and faucets are backed by strict quality control and factory warranties. Our products are tested to meet global standards before shipping. Buyers can purchase wholesale with confidence, knowing that our company provides after-sales service and consistent support. When ordering ODM products, customers also benefit from tailored guarantees linked to their specific designs.