The kitchen sink is an integral part of every home kitchen and plays a crucial role in daily kitchen use. With the continuous evolution of modern kitchen design, more and more kitchen sinks are adopting advanced manufacturing processes. Among them, press-formed stainless steel kitchen sinks have become a widely adopted choice in the market due to their outstanding performance and advantages.

The press-forming process, which involves heating stainless steel sheets to high temperatures and then forming them using hot stamping technology, can produce kitchen sinks with high structural strength, beautiful shapes, and diverse functions. Compared to traditional cold forming methods, this process not only allows for more complex and diverse designs, but also ensures durability and aesthetics. This article will detail the advantages of press-formed stainless steel kitchen sinks and explore why they are an ideal choice for modern kitchens.

What is a press-formed stainless steel kitchen sink?

Press-formed stainless steel kitchen sinks are made using a hot stamping process. By heating stainless steel sheets to a certain temperature and then using a press machine to form them, this process can produce complex geometries. Compared to cold forming, press-forming offers more design possibilities while maintaining structural stability. This makes press-formed stainless steel kitchen sinks not only highly strong but also offer a unique design to meet the needs of diverse users.

What are the advantages of press-formed stainless steel kitchen sinks?

Advantages of press-formed stainless steel kitchen sinks:

1. High strength

2. Complex geometries

3. Reduced springback and defects

4. Customizable material properties

5. Improved corrosion resistance

6. Easy cleaning and maintenance

7. Energy-saving and environmentally friendly

1. High strength

One of the greatest advantages of press-formed stainless steel kitchen sinks is their exceptional strength. Thanks to the use of hot stamping technology, this process significantly enhances the sink's tensile strength and impact resistance. While traditional sink manufacturing processes often require thicker metal sheets to ensure strength, hot stamping allows for thinner metal sheets while maintaining the stainless steel sink's structural integrity.

This high strength makes press-formed stainless steel sinks more durable and less susceptible to deformation or damage from long-term use or accidental impacts. Furthermore, the high strength of stainless steel kitchen sinks effectively withstands the wear and tear of daily use, keeping them in excellent working condition, especially in busy kitchen environments.

2. Complex Geometric Shapes

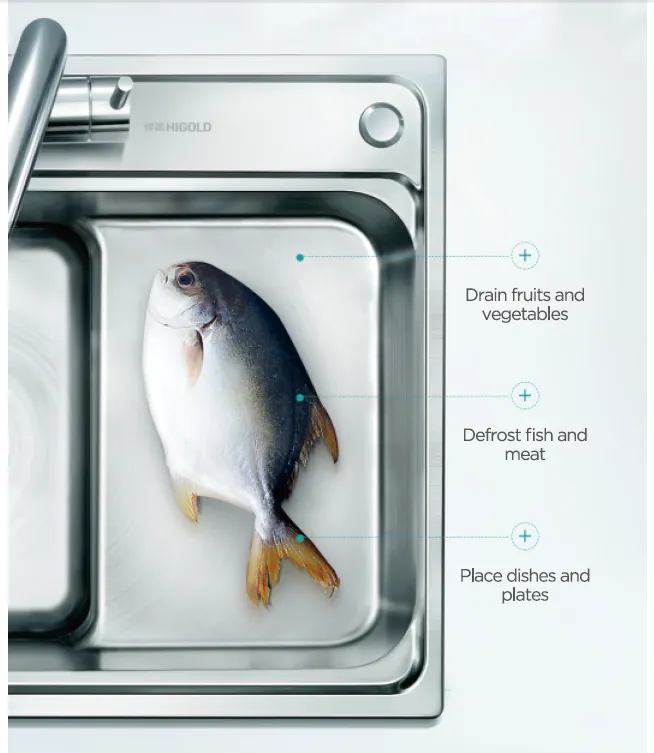

Another significant advantage of the press-forming process is its ability to produce complex geometries. Traditional cold-forming techniques have limitations in shape design, especially for sinks requiring intricate designs and complex curves, which are often impossible to achieve with cold-forming. However, press-formed stainless steel kitchen sinks can be formed into a variety of complex shapes that cannot be achieved with hot stamping.

This advantage enables designers to design sinks with unique shapes and diverse functions to suit different kitchen styles and needs. For example, the concave curves, specialized edge designs, and more user-friendly internal structures required in modern kitchen designs can all be easily achieved with hot stamping.

3. Reduced Springback and Defects

Springback and deformation of metal sheets are common in traditional metal forming processes. In particular, uneven force distribution during the forming process can cause warping or springback, impacting the final quality of the sink. Press-formed stainless steel kitchen sinks, through hot stamping, effectively reduce this springback and deformation.

The hot stamping process minimizes the internal stresses generated in the metal during the forming process, resulting in a smoother sink surface and avoiding springback defects such as cracks and fissures. This not only improves the quality of the sink but also extends its lifespan, ensuring it maintains its flawless appearance and functionality over extended use.

4. Customizable Material Properties

The press-forming process also offers a unique advantage: the ability to customize the material properties of different areas of the sink. During the hot stamping process, manufacturers can precisely control the metal forming process based on the specific needs of each area of the sink, imparting specific mechanical properties to specific areas.

For example, some parts of a sink may require higher corrosion resistance, while others require greater scratch resistance. Press-forming technology allows the material properties of each area to be precisely tailored to meet the varying performance requirements. This customization allows stainless steel kitchen sinks to meet the needs of diverse households while providing a superior user experience.

5. Improved Corrosion Resistance

Press-formed stainless steel sinks offer superior corrosion resistance due to their material selection and production process. Traditional sink materials are susceptible to corrosion and oxidation when exposed to water for a long time. This is especially true in kitchen environments, where frequent contact with grease, salt, and acidic substances exacerbates corrosion.

Pressed stainless steel kitchen sinks, however, utilize high-quality stainless steel with strong corrosion resistance, effectively resisting corrosion caused by water and chemicals, maintaining their luster and strength. This corrosion resistance makes them particularly durable in humid and fumes-prone kitchen environments, reducing the need for repairs and replacements due to corrosion.

6. Easy Cleaning and Maintenance

Pressed stainless steel sinks are relatively easy to clean due to their smooth, flat surface, which resists stains and scale. Compared to sinks made of some traditional materials, stainless steel kitchen sinks are less susceptible to bacteria and dirt accumulation, making them easier to maintain.

Furthermore, stainless steel sinks generally require no special cleaning and maintenance; ordinary detergents and a soft cloth are sufficient for daily cleaning. Due to their high corrosion resistance, the sink surface is less susceptible to damage from detergents and everyday cleaning tools, ensuring they remain pristine for a long time.

7. Energy Saving and Environmental Protection

Compared to other metal forming methods, hot stamping utilizes energy more efficiently during the production process. This not only helps reduce production costs but also reduces energy consumption and environmental impact. By utilizing thinner sheet metal, the press-forming process is more energy-efficient and environmentally friendly. This also results in lighter finished sinks, making them easier to transport and install.

These energy-saving and environmentally friendly features meet the resource conservation and environmental protection requirements of modern kitchenware manufacturing, making stainless steel kitchen sinks more popular with consumers.

Press-Formed Stainless Steel Kitchen Sinks vs. Traditional Welded Sinks: Comparison

Features | Pressed stainless steel kitchen sinks | Traditional welded stainless steel kitchen sinks |

| Strength | Strong integrity, high tensile strength, and resistance to deformation | Welded areas are fragile and prone to cracking |

| Shape complexity | Enables deeper and larger sinks | Due to welding limitations, the shape is relatively uniform |

| Defect control | No welds, reducing cracking and warping | Weld defects and deformation are common |

| Customizability | Customizable material properties for different areas | The material is uniform, making local reinforcement difficult |

How can I be sure Higold will meet my delivery deadlines?

Higold uses a digitalized production management system that tracks orders in real time and adjusts production schedules for priority shipments. Historical performance, including on-time delivery to global clients like Costco, demonstrates the company's reliability in meeting tight deadlines.