As one of the most frequently used kitchen appliances, sinks are bound to experience various types of wear and tear. This wear and tear not only affects the sink's aesthetics but can also negatively impact its lifespan. Different sink types experience varying degrees and types of wear due to their material.

Among various kitchen sink materials, quartz composite sinks are favored by many consumers for their superior performance. However, composite quartz sinks are not immune to wear and tear. So, what is the most wear-resistant kitchen sink? Considering the sink's material, surface treatment, and usage habits, composite quartz sinks, while extremely durable, are not completely immune to wear and tear.

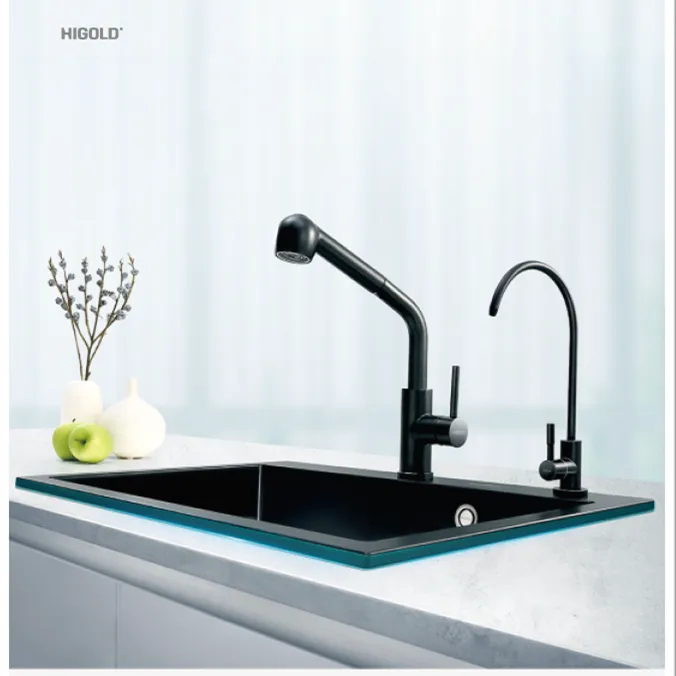

Why are composite quartz sinks the most wear-resistant sinks?

Composite quartz sinks are made by combining natural quartz particles and resin through a special process, offering many unique advantages.

Advantages of Composite Quartz Sinks:

1. Wear Resistance

2. High Temperature Resistance

3. Stain Resistance

4. Corrosion Resistance

· Wear Resistance: One of the greatest advantages of composite quartz sinks is their excellent wear resistance. Quartz itself is an extremely hard mineral with a high hardness, so the surface of composite quartz sinks is generally highly scratch-resistant. They can withstand the abrasion of most kitchen utensils (such as cutlery, knives, and pots).

· High Temperature Resistance: Composite quartz sinks have very high heat resistance, capable of withstanding temperatures up to 280°C. This allows them to withstand direct contact with hot pots and hot water without deformation or damage.

· Stain Resistance: The surface structure of quartz composite sinks is dense, making them less susceptible to dirt and stains, making them highly stain-resistant. Even if daily cleaning is not done regularly, the surface is less susceptible to oil and stains, keeping the sink clean.

· Corrosion Resistance: Composite quartz sinks are highly resistant to acid and alkali corrosion and are not easily corroded by common kitchen cleaners and chemicals.

Although quartz composite sinks offer many advantages, particularly durability and wear resistance, they are not completely impervious to wear and tear. In daily use, improper handling or improper cleaning methods can cause wear, scratches, and discoloration on the surface of quartz composite sinks.

What causes wear and tear on composite quartz sinks?

The causes of wear and tear on composite quartz sinks include:

1. Excessive friction

2. Improper cleaning

3. Thermal shock

4. Acidic attack

5. Rough use

1. Excessive friction

Although composite quartz sinks are relatively hard, frequent scrubbing with tools such as steel wool and hard brushes, or direct abrasion with sharp tools, can still cause scratches and wear on the surface. This is especially true for hard objects such as iron and knives, where intense friction can damage the surface and cause permanent scratches.

2. Improper cleaning

Improper cleaning methods are also a major cause of wear and tear on quartz composite sinks. Using detergents containing particles or overly harsh chemicals can scratch the sink surface and even damage the protective coating, accelerating wear.

3. Thermal Shock

Although quartz composite sinks are heat-resistant, placing extremely hot pots or food directly into the sink during use can cause thermal shock, leading to cracking or deformation of the sink surface. Long-term thermal shock can reduce the sink's durability and gradually wear out the surface.

4. Acidic Attack

Although composite quartz sinks are highly corrosion-resistant, prolonged exposure to strong acids (such as vinegar and lemon juice), especially if these acids are not promptly removed during cleaning, can corrode the surface and cause signs of wear.

5. Rough Use

When using composite quartz sinks, some households may habitually place heavy or hard objects into the sink. This behavior can cause unnecessary scratches on the surface and shorten the sink's lifespan.

How to identify worn composite quartz sinks?

How to identify worn composite quartz sinks:

1. Scratches and scratches

2. Surface discoloration

3. Color fading and color shift

4. Cracks and breaks

5. Rough surface

1. Scratches and scratches

Although quartz composite sinks are highly scratch-resistant, improper use, particularly cleaning with hard brushes or steel wool, can still cause minor scratches or scratches. While these scratches may not necessarily affect the sink's functionality, they can affect its aesthetics and may deepen over time.

2. Surface discoloration

The surface of composite quartz sinks may discolor if exposed to acidic or alkaline substances for extended periods. This is especially true for dark or light-colored composite quartz sinks. Prolonged contact with certain foods (such as coffee and soy sauce) can cause discoloration, affecting the sink's aesthetics.

3. Discoloration and Color Variation

The surface of a composite quartz sink may fade with long-term use. This is especially true for low-quality quartz composite sinks that haven't been adequately surface-treated during production. This can cause color variations or fading over time.

4. Cracks and Damage

Although composite quartz sinks are heat-resistant, in extreme cases, thermal shock or excessive impact can cause cracks or damage to the surface. This not only affects the sink's appearance but can also affect its functionality.

5. Rough Sink Surface

Over time, the surface of a composite quartz sink may lose its smoothness due to improper cleaning or prolonged use. The once smooth surface may become rough, affecting the sink's cleaning effectiveness.

How to Reduce Wear on Composite Quartz Sinks?

To maintain the lifespan and aesthetic appeal of quartz composite sinks, consumers should follow some basic usage and care guidelines to avoid excessive wear and tear.

1. Avoid using hard objects to scrub the sink

Avoid using steel wool, rough brushes, or other tools to clean the sink. It's best to use a soft sponge or cloth to wipe the sink surface to minimize scratches.

2. Clean the sink surface promptly

After each use, rinse the sink with clean water immediately to prevent food residue or chemicals from remaining on the surface, which can cause corrosion or discoloration.

3. Avoid thermal shock

When using a composite quartz sink, avoid placing pots or baking sheets directly from the stove into the sink to prevent thermal shock, which can cause cracks or damage to the sink surface.

4. Use a neutral detergent

When cleaning a quartz composite sink, choose a neutral detergent or a dedicated sink cleaner. Avoid using cleaning products containing particles or strong acids or bases to prevent damage to the sink surface.

5. Regular Maintenance and Care

Composite quartz sinks require regular maintenance. Use a quartz sink care solution for surface treatment to maintain a smooth and shiny surface.

What is the lead time for customized sink orders at Higold?

Lead time for customized stainless steel sink orders generally ranges from 25 to 35 days, depending on complexity and quantity. Higold’s streamlined production system and in-house tooling allow for faster turnaround compared to many competitors. The company provides detailed production schedules and status updates for all custom orders. Contact the sales team for accurate lead time estimates based on your specific purchasing plan.