Undermount kitchen sinks are an ideal choice for many families due to their simple, aesthetically pleasing appearance and easy cleaning. Unlike traditional countertop sinks, undermount sinks conceal the sink rim beneath the countertop, creating a seamless connection between the countertop and sink.

While this design is visually appealing and enhances the aesthetics of a kitchen, it can also present installation and maintenance challenges. One common problem encountered by many consumers is undermount kitchen sinks falling.

Undermount kitchen sinks can fall over time after installation, typically manifesting as the connection between the sink and the countertop gradually loosening, or even falling during use. This not only affects the kitchen's appearance but can also cause inconvenience and even damage the countertop and sink itself.

To help address this issue, this article will explore the causes and solutions for undermount kitchen sinks falling from multiple perspectives, analyzing the underlying causes and providing consumers with effective prevention and repair recommendations.

What is the mounting structure of an undermount kitchen sink?

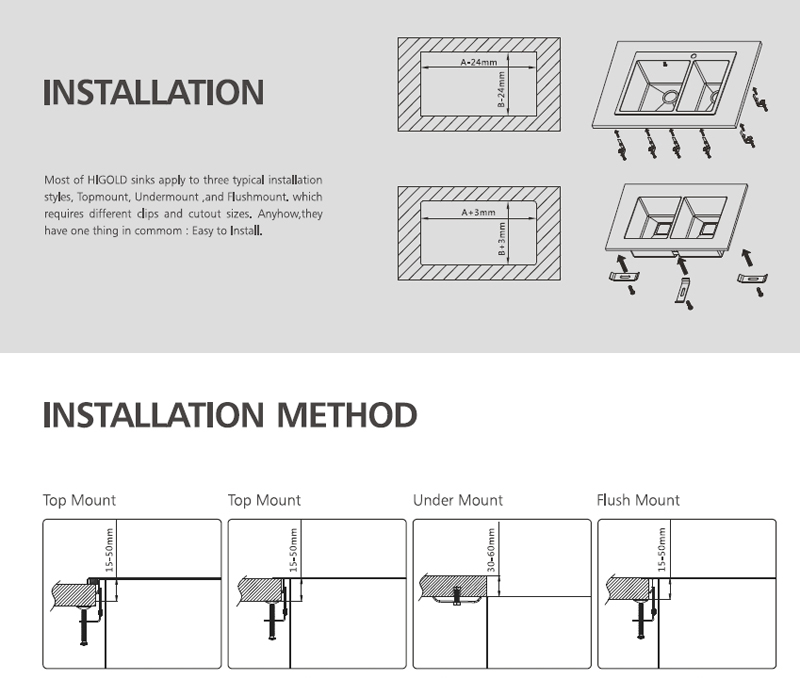

An undermount sink is typically attached to the countertop using specialized fixing brackets, adhesives, and bolts. Key installation steps include firmly securing the sink rim to the countertop and providing additional support with brackets or other reinforcements.

Undermount sink installation requirements are stringent, as the weight of the sink must be evenly distributed to prevent excessive pressure on any one side. Improper installation or substandard materials and fixings can easily cause the sink to fall or become loose during use.

What causes undermount kitchen sinks to fall?

Causes of undermount kitchen sinks falling include:

1. Improper installation

2. Problems with the countertop material

3. Problems with the quality of the adhesive or fixings

4. Poor contact between the sink and the countertop

5. Uneven weight distribution of the sink

6. Wear and tear from long-term use

1. Improper installation

Improper installation is one of the most common causes of undermount kitchen sinks falling. When installing an undermount sink, the sink must form a secure connection to the countertop. This typically relies on strong adhesives, supports, and bolts to maintain the sink's stability. Failure to ensure these fasteners are secure during installation, or improper adhesive application, can cause the sink to loosen during use, leading to it falling.

Improper installation can also be caused by inappropriate tools or unprofessional installers. If the installer doesn't strictly follow installation specifications, they may overlook key details when securing the sink, resulting in it not being adequately secured to the countertop.

2. Countertop Material Issues

The quality of the countertop material directly impacts the sink's securement. Undermount sinks typically require a tight bond beneath the countertop, and the hardness and thickness of the countertop material are crucial for distributing the securing force. If the countertop material is too fragile or insufficiently thick, it may not be able to support the sink's weight, causing it to loosen or fall.

For example, if a quartz or engineered stone countertop is not thick or strong enough when installing an undermount sink, the sink may fall after prolonged use due to insufficient load-bearing capacity. In contrast, natural stone or specially treated reinforced countertops offer better retention.

3. Adhesive or Fixing Material Quality Issues

When installing an undermount sink, the quality of the adhesive or fixing material used is crucial. Poor-quality adhesives can gradually lose their strength over time, causing the sink to become loose and eventually fall. Frequent steam, heat fluctuations, and the use of cleaning agents can all affect the adhesive's durability, especially in kitchen environments.

Furthermore, if installation procedures are not followed, adhesive is applied unevenly, or an inappropriate adhesive material is used, the sink may become loose and increase the risk of a fall.

4. Poor Contact Between Sink and Countertop

When installing an undermount kitchen sink, the rim must be completely flush against the countertop. Insufficient contact between the rim and the countertop, or gaps in the contact area, can make the sink unstable and increase the risk of a fall. Failure to ensure the rim is flat or angled correctly during installation can also compromise the sink's stability.

5. Uneven Weight Distribution of the Sink

The weight distribution of a sink also significantly impacts its stability. Undermount kitchen sinks are typically installed below the countertop, placing their weight directly on the countertop. If the sink's design and installation fail to ensure even weight distribution, particularly if the rim and base are not adequately supported, excessive pressure on certain parts can result, leading to a fall.

6. Wear and Aging with Long-Term Use

Even if the sink is properly secured initially, long-term use can cause some materials to age or wear, especially in humid, fumes-prone kitchen environments. Adhesives can gradually degrade due to thermal expansion and contraction, and the contact surface between the sink and the countertop can lose its adhesiveness due to wear and tear, causing the sink to become loose.

Over time, undermount kitchen sinks may be affected by factors such as water vapor, temperature fluctuations, and cleaning agents, which can degrade the mounting materials. This can eventually lead to the sink falling or becoming unstable.

How can I fix an undermount kitchen sink falling?

1. Ensure Professional Installation

To avoid the risk of an undermount kitchen sink falling, it is crucial to ensure that the sink is installed by a professional. During installation, strictly follow the installation instructions and use the appropriate tools and materials. During installation, ensure a secure connection between the sink and the countertop to avoid poor contact or loose anchoring.

2. Choose the Right Countertop Material

When selecting countertop material, consider its strength and thickness. The countertop material should be strong enough to support the weight of the sink. Natural stone materials such as marble, granite, or thick composite countertops generally provide better support, preventing sinks from falling due to fragility.

3. Use High-Quality Adhesives and Fixing Materials

Ensure that high-quality adhesives and fixing materials are used and applied correctly according to the manufacturer's instructions. High-quality adhesives can withstand the humidity and temperature fluctuations in the kitchen, maintaining the stability of the sink. The fixing materials should also be of the appropriate type to ensure they have sufficient weight-bearing capacity to support the sink.

4. Regular Inspection and Maintenance

After installing an undermount kitchen sink, it's essential to regularly inspect the sink's securement. Over time, problems such as aging adhesive and loosening of the mounting brackets may occur. Regularly inspect the points of contact between the sink and the countertop. If any signs of looseness are found, repair or reinstall them promptly to prevent a fall.

5. Properly Distribute the Sink's Weight

When using an undermount sink, ensure that the weight within the sink is properly distributed. Avoid placing excessive weight on one side of the sink, which can cause uneven weight distribution. If possible, use a support bracket or other reinforcement to provide additional support for the sink and ensure long-term stability.

Why choose Higold as your kitchen sink supplier?

Higold Group Co., Ltd. is one of China’s leading kitchen hardware companies, established in 2004. With more than 2000 employees and 200,000㎡ production area, our factory delivers high quality stainless steel sinks and faucets at competitive prices. We specialize in ODM projects, supplying international brands with CUPC, CSA, and CE certified products. Customers worldwide trust Higold for wholesale purchasing, bulk discounts, and reliable supply chain management.