As a kitchen facility that is both beautiful and practical, composite kitchen sinks have become a common choice in modern kitchen decoration due to their diverse materials and easy-to-clean characteristics. However, the sealing problem of composite kitchen sinks often troubles many consumers, especially during the installation and use process, how to ensure the sealing of the sink and prevent water leakage has become a question worth pondering.

Do composite kitchen sinks need to be sealed? If necessary, how to ensure the sealing effect? This article will start from the basic structure of composite kitchen sinks, deeply analyze the importance of sink sealing, and provide specific sealing methods and precautions to help consumers avoid water leakage during installation and maintenance and improve the use experience of kitchen sinks.

What are composite kitchen sinks?

Composite kitchen sinks are sinks made of two or more different materials through a composite process. Common composite kitchen sinks include stainless steel and quartz composite, stainless steel and ceramic composite, quartz and resin composite, etc. Composite kitchen sinks have shown good performance in hardness, corrosion resistance, antifouling, and antibacterial properties due to their unique combination of materials. In particular, quartz composite kitchen sinks are widely used in modern homes and commercial kitchens because of their beautiful appearance similar to natural stone and the durability of stainless steel.

Composite kitchen sinks usually adopt a multi-layer structure, including the sink body and the bottom plate and side plates connected to the countertop. The characteristics of this structure require special attention to the sealing of the joint between the sink and the countertop during the installation process. If the sealing is not good, there may be hidden dangers of water seepage or leakage between the sink and the countertop, affecting the dryness and hygiene of the kitchen, and may even cause damage to the kitchen decoration.

Why do composite kitchen sinks need to be sealed?

The sealing of composite kitchen sinks is of great significance to the service life of the sink, the kitchen environment and home safety. Although the material of the composite kitchen sink itself has good water resistance, the joint between the sink and the countertop is still a potential water seepage area. Whether in the normal use of the sink or during daily cleaning, if the sealing is not properly handled, water may leak from the edge of the sink to under the countertop or even into the cabinet under the sink. Long-term water seepage will not only affect the structure of the countertop and cabinet, but may even cause water damage, mildew and other problems.

The following are several key reasons why composite kitchen sinks need to be sealed:

● Prevent water leakage: The joint between the sink and the countertop is often the "weak link" for water leakage. Especially in daily use, the sink will be subjected to large water flow and frequent impact. If there is no effective sealing treatment, water may penetrate through the gap to the bottom of the countertop and then penetrate into the cabinet, causing unnecessary losses.

● Avoid deformation or damage to the sink: Composite kitchen sinks are mostly made of resin, quartz or ceramic, which are easily eroded by water after long-term contact with water. Sealing can effectively prevent moisture from penetrating into the bottom and sides of the sink, and prevent the sink from deformation or surface damage due to moisture accumulation.

● Improve the hygienic environment of the kitchen: If the gaps around the sink are not sealed well, moisture and dirt are easy to accumulate, becoming a breeding ground for bacteria. Good sealing can not only prevent water accumulation around the sink, but also reduce the adhesion of dirt, keeping the kitchen clean and hygienic.

● Extend the service life of the sink: Sealing can effectively reduce the wear of the joints between the sink and the countertop, protect the sink body from water erosion, and thus extend the service life of the sink. In particular, quartz composite kitchen sinks, whose surfaces are easily affected by water stains, dirt and detergents, sinks with good sealing can reduce the penetration of water stains.

How to seal composite kitchen sinks?

The sealing of sinks is usually carried out during the installation process. Sealing mainly includes the sealing of the gaps at the connection between the sink and the countertop, as well as the sealing of the sink and other accessories (such as drain pipes, waste pipes, etc.). The following will introduce the sealing steps, selection of sealing materials and sealing techniques of composite kitchen sinks in detail.

1. Preparation

Before performing the sealing operation, make sure that the installation area and materials are clean. Cleaning the stains, oil stains and scale in the contact area between the kitchen sink and the countertop is a very important step. Use a mild detergent and a soft cloth to wipe clean, making sure that the surface is free of dust and dirt. Next, check whether there are obvious gaps and uneven areas between the sink and the countertop.

2. Choose the right sealing material

Choosing the right sealing material is crucial to ensure the sealing effect. Common sink sealing materials are mainly the following:

● Silicone sealant: Silicone sealant is a sealing material commonly used in kitchens and bathrooms. Because of its good water resistance and antibacterial properties, it is usually used to seal the joints between composite kitchen sinks and countertops. Silicone sealant can effectively fill the gap and form a waterproof barrier.

● Polyurethane sealant: Polyurethane sealant is a sealing material with superior performance that can maintain elasticity and durability during long-term use. Compared with silicone, polyurethane sealant has stronger water resistance and high temperature resistance, and is suitable for sealing between kitchen sinks and countertops, especially in commercial kitchens.

● Acrylic sealant: Acrylic sealant usually has strong adhesion and excellent corrosion resistance, and is suitable for the connection between quartz composite kitchen sinks and countertops. It has strong resistance to moisture and can maintain good sealing performance in harsh environments.

● Rubber gasket: In some installations, especially when the joint between the kitchen sink and the countertop is large, in addition to sealant, rubber gaskets can also be used to enhance the sealing effect. Rubber gaskets can effectively reduce moisture penetration at the joint and enhance the stability of the seal.

3. Sealing operation steps

● Apply sealant: First, apply a layer of sealant evenly on the joint between the kitchen sink and the countertop. Use a special sealant gun to apply the sealant evenly along the joint line to ensure that each gap is fully filled.

● Compact the sealant: After applying the sealant, use a scraper or wet cloth to gently press the sealant to ensure that it fits tightly to the contact surface between the sink and the countertop. Be careful not to let the sealant overflow from the gap to keep it neat.

● Remove excess sealant: When the sealant is initially cured, use a clean wet cloth or sponge to wipe off the excess sealant on the surface of the kitchen sink to avoid affecting the appearance and cleanliness.

● Wait for curing: Follow the instructions of the sealant and maintain a certain curing period, usually 24 hours, to ensure that the sealant is completely dry and achieves the best effect. Avoid contact with moisture during the curing period to avoid affecting the sealing effect.

4. Regular inspection and maintenance

After the sealing work is completed, it is very important to regularly check the sealing condition between the composite kitchen sinks and the countertop. As the use time increases, the sealant may be affected by water flow, heat or physical wear, resulting in a decrease in sealing effect. Therefore, every time you clean the kitchen, it is recommended to check whether there is any leakage at the joints of the kitchen sink and repair it in time.

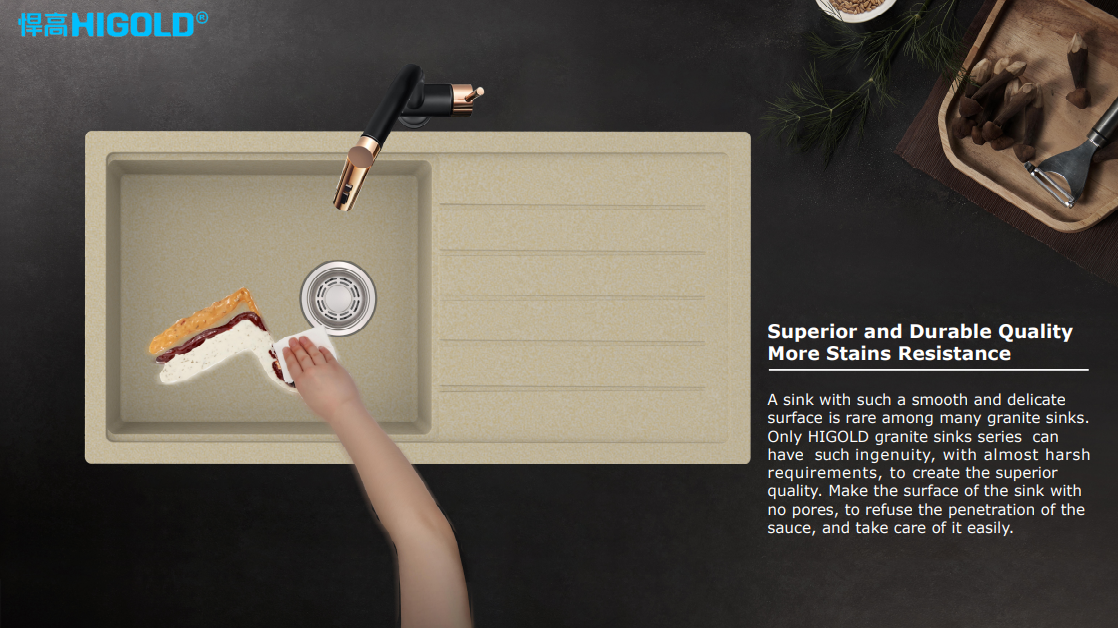

Get Stainless Steel Sinks and Faucets at Low Prices from Higold

Higold Group offers a wide range of stainless steel kitchen sinks, composite kitchen sinks and faucets at low prices, without compromising on quality. Our products are made from premium SUS304 stainless steel and are designed to meet the highest industry standards. We cater to both small and large orders, offering flexible solutions and fast turnaround times. With years of experience and a strong presence in over 86 countries, we are your trusted partner for kitchen products. Contact us for a wholesale quote and explore our discounts.