In kitchen renovations, the sink installation method directly impacts user experience, aesthetics, and daily cleaning efficiency. Among various sink installation methods, undermount sinks have gradually become the mainstream choice for modern kitchens due to their simple appearance, ease of cleaning, and seamless integration with the countertop.

However, many people have the same question during the renovation process:

"What exactly secures an undermount kitchen sink?"

Undermount kitchen sinks don't rely on the countertop edge for support like countertop sinks; they are suspended below the countertop, making the securing method crucial. The securing of an undermount sink involves the coordination of adhesives, mechanical fasteners, countertop material support, and structural design.

This article will provide an in-depth analysis from a professional perspective of the securing principles, structural key points, installation mechanisms, and why these securing methods are essential for long-term use of undermount sinks.

What are the key structural components that secure an undermount sink?

For many users, an undermount installation may seem like the sink is "attached to the bottom of the countertop," but it actually involves a rigorous structural design. To answer the question, "What secures an undermount sink?", we need to break down the main securing components.

1. Strong Adhesives are a Core Securement Method

A key to securing an undermount kitchen sink is using professionally applied stone adhesive, structural adhesive, or epoxy adhesive.

The adhesive plays the following roles in the entire securing system:

It firmly bonds the sink edge to the countertop.

It provides even support.

It prevents water from seeping to the bottom of the countertop.

High-quality structural adhesives can withstand long-term tensile, sagging, and impact forces, ensuring the undermount kitchen sink's stability.

2. Mechanical Fasteners Provide Additional Support

Besides adhesives, another important securing method is using metal brackets, clips, or hooks.

These mechanical structures are typically installed under the countertop and secured to the sink edge with screws, providing double protection.

The functions of mechanical fasteners include:

• Preventing the undermount sink from detaching under long-term pressure.

• Sharing the stress with the adhesive.

• Ensuring the sink remains level for a long time.

Even if the adhesive ages slightly after many years, the mechanical fasteners still ensure the undermount sink remains firmly in place.

3. The Countertop Material Itself Provides Crucial Support

Undermount sinks differ from top-mount sinks in that they have higher requirements for the countertop material. Countertops suitable for undermount installation typically include:

• Quartz stone

• Granite

• Marble

• Sintered stone

• Solid surface materials

These materials have high hardness and sufficient density, thus providing a stable adhesive surface for a secure bond to the sink.

The harder the countertop, the more reliable the undermount kitchen sink's fixation.

Why do undermount sinks require both adhesive and mechanical fasteners?

Many people have a question when learning about undermount sinks: "If the structural adhesive is so strong, why use mechanical fasteners?"

To understand why, we need to understand the stresses underway during long-term use of an undermount sink.

1. Adhesive alone cannot withstand all forces

Even the highest quality structural adhesives will gradually age over time.

The kitchen environment also includes:

• Temperature changes

• Prolonged humidity

• Cleaning chemicals

• Impacts from heavy objects

These all affect the lifespan of the adhesive, so relying solely on adhesive is not stable.

2. Mechanical fasteners maintain structural stability over the long term

Metal brackets, clamps, and other mechanical structures do not age or become damp, thus providing continuous stable support and ensuring the undermount kitchen sink remains securely fixed and does not sag even when the adhesive slightly degrades.

3. Two fixing methods complement each other

The dual fixing mechanism gives undermount sinks extremely high safety.

• Adhesive ensures a tight fit.

• Mechanical fasteners provide long-term tensile strength.

• The countertop provides overall support.

These three components together form a complete and stable mounting structure.

What are the key roles of adhesives in undermount sinks?

Adhesives are one of the core components of the entire undermount kitchen sink mounting system. Many people think it simply "glues the sink together," but its role in the overall structure is far more important than imagined.

1. Achieving a Seamless Fit

The core of an aesthetically pleasing undermount installation is the seamless transition between the countertop and the sink.

The adhesive's functions include:

• Filling tiny gaps

• Ensuring a perfect fit between the bottom of the countertop and the edge of the sink

• Preventing water from seeping into the countertop

This makes the entire structure both beautiful and practical.

2. Bearing Continuous Downward Force

Sinks frequently hold pots, pans, and large amounts of water, making them not only heavy but also subject to frequent changes in volume.

The tensile strength of the adhesive must be sufficient to withstand the weight from below; therefore, the adhesive must possess:

• High strength

• High water resistance

• Resistance to temperature differences

• Tensile strength

This is why undermount kitchen sinks require specialized structural adhesives.

3. Maintaining Structural Stability and Preventing Displacement

The adhesive not only provides fixation but also ensures the sink does not shift due to vibration or impact during use.

This is especially important in large single-bowl or deep-basin structures.

What role do mechanical fasteners play in undermount sinks?

The adhesive is the core of the fixation, but the mechanical fasteners are the "key to ensuring stability." Many users are unaware of the importance of these small components.

1. Preventing Sink Sagging

Mechanical fasteners are typically installed under the countertop, pulling the sink edge upwards and securing it with screws, creating an upward thrust to prevent the sink from sagging due to long-term weight.

2. Enhancing Overall Structural Strength

Sinks are frequently subjected to impacts, knocks, and vibrations during use.

Mechanical fasteners can:

• Counteract the force of sudden impacts

• Prevent adhesive from bearing pressure alone

• Enhance overall durability

Making undermount kitchen sinks safer and more stable.

3. Provide adjustability

During installation, mechanical fasteners can fine-tune the sink's level, allowing for a more precise fit with the countertop.

This is something adhesive cannot do.

Why do undermount sinks have higher requirements for countertop materials?

For an undermount kitchen sink to be securely fixed, the countertop must be able to withstand the adhesive's adhesion and the weight of the sink.

1. The countertop must have sufficient rigidity

Soft countertops such as:

• Wood-based panels

• Low-density fiberboard (LDF)

• Some composite boards

These are prone to swelling, warping, or delamination due to prolonged exposure to moisture and are unsuitable as a fixing base for undermount sinks.

2. High-density stone countertops are more suitable

Hard countertops include quartz, marble, and granite, which have the following characteristics:

• Excellent compressive strength

• Resistant to deformation

• Non-absorbent

Therefore, they provide a stable bonding surface and long-term support.

3. The flatness of the countertop bottom directly affects the sink's stability

If the countertop bottom is uneven, the adhesive will not adhere completely, and mechanical fasteners will not be able to effectively bear the force. Therefore, hard stone countertops are the best match for undermount sinks.

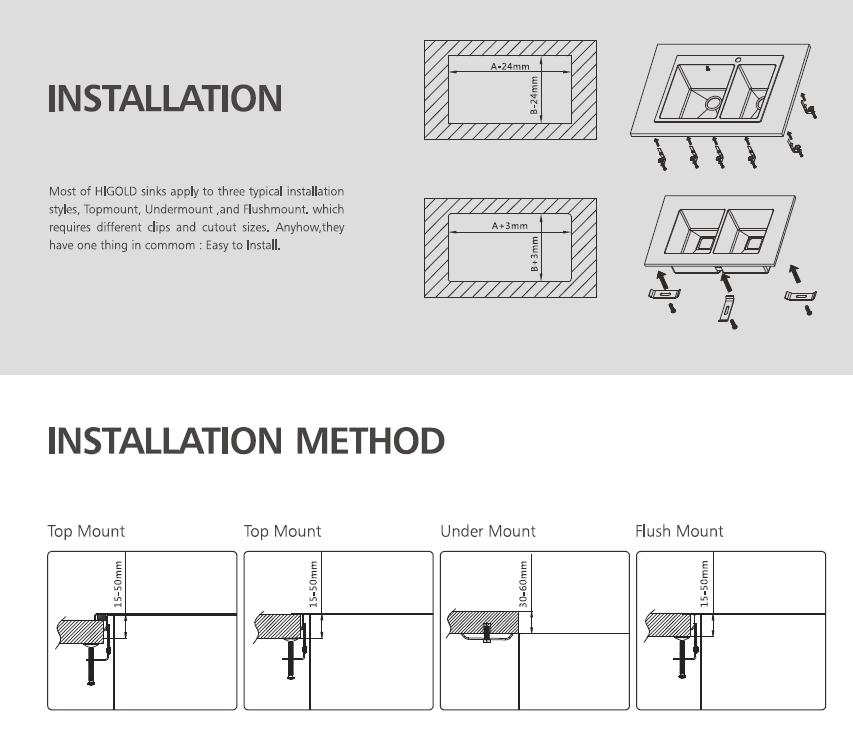

What are the important steps in the actual installation process of an undermount sink?

To ensure the undermount kitchen sink is secure and does not loosen, the installation steps must be precise and standardized, as each step directly affects the structural stability.

1. Grind and clean the bonding surface

Ensure the bottom of the countertop is free of dust, oil, and moisture.

2. Apply structural adhesive evenly

The adhesive must be applied evenly, covering the entire edge of the sink, ensuring no gaps.

3. Install Mechanical Fixtures

The mechanical supports must be evenly distributed according to the sink dimensions to ensure balanced force distribution.

4. Adjust Level

The installer must fine-tune the sink's level using the fixtures to ensure a perfect fit.

5. Wait for Adhesive to Cur

The structural adhesive requires time to cure; it cannot be used or filled with water before curing is complete.

Why does an undermount sink require a structurally sound basin design?

Besides the adhesive and fixtures, the sink's structural design also determines its secure installation.

1. Smooth Edges

The smoother the sink's edges, the more stable the adhesive surface, making it easier to adhere tightly to the countertop.

2. Sturdy, Non-deforming Material

Material that is too heavy may cause long-term sagging, while material that is too brittle may break during installation.

This is why stainless steel undermount sinks are so popular, because they are:

• Lightweight

• High strength

• Good toughness

• Easy to fix

• Non-deformable

3. Sink depth affects stress distribution

Deep sinks require a stronger fixing system; otherwise, the adhesive and support components may be subjected to excessive pressure.

What are the combined factors contributing to the stability of an undermount sink?

For an undermount kitchen sink to be stable and secure, several parts must work together.

1. Adhesive strength

Ensuring a strong and lasting bond.

2. Mechanical fixing supports

Providing long-term structural stability.

3. Countertop hardness

Providing a reliable base.

4. Sink material and structure

Ensuring balanced stress and preventing deformation.

5. Proper installation process

Ensuring each step meets standards.

When all these conditions are met, the stability of the undermount kitchen sink reaches its optimal state.

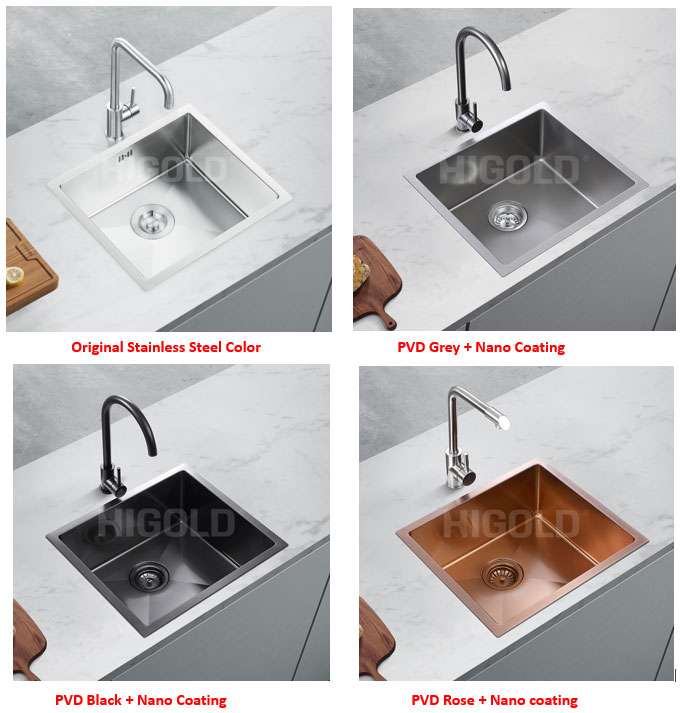

Does Higold Provide Sink Accessories and Kitchen Solutions?

Yes. Higold offers a complete range of accessories, including strainers, soap dispensers, roll-up racks, drainpipes, cutting boards, and matching stainless steel faucets. These accessories complement our kitchen stainless steel sinks, making them ideal for bundled wholesale sales. Buying a full solution from Higold simplifies sourcing and enhances retail product appeal.